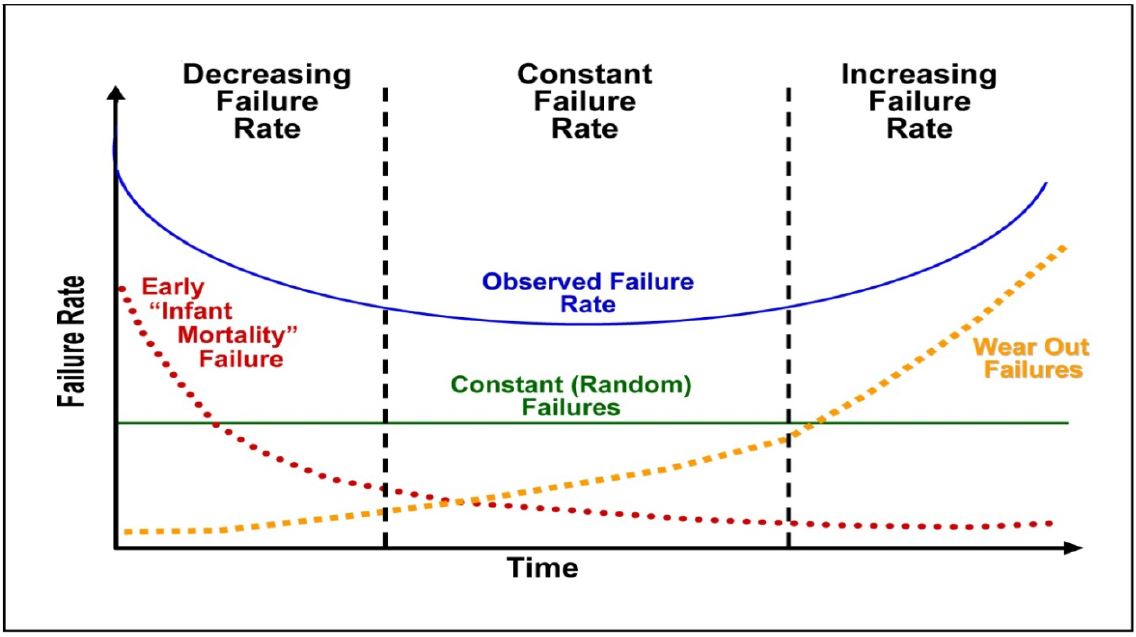

A couple decades ago, the Union of Concerned Scientists (UCS) published what it called the “bathtub curve.” This curve charted the expected and observed performance of nuclear reactors from initial operation until final shutdown. The main finding of note was that when a reactor first comes online, typically there are a large number of problems as the operators learn the technology of that specific reactor, issues resulting from construction deficiencies surface, etc. After a shakedown period of a year or two, reactor operations typically settle down for quite a while, with most reactors operating relatively efficiently. But as time goes on, problems associated with reactor aging–components being exposed to extraordinarily high heat and radiation as well as the simple reality that all things mechanical break down over time–begin to materialize and safety issues begin to mount again.

A couple decades ago, the Union of Concerned Scientists (UCS) published what it called the “bathtub curve.” This curve charted the expected and observed performance of nuclear reactors from initial operation until final shutdown. The main finding of note was that when a reactor first comes online, typically there are a large number of problems as the operators learn the technology of that specific reactor, issues resulting from construction deficiencies surface, etc. After a shakedown period of a year or two, reactor operations typically settle down for quite a while, with most reactors operating relatively efficiently. But as time goes on, problems associated with reactor aging–components being exposed to extraordinarily high heat and radiation as well as the simple reality that all things mechanical break down over time–begin to materialize and safety issues begin to mount again.

As we have been seeing at reactors across the nation, especially those in competitive markets, when aging-related safety problems arise, so do economic problems. It takes a lot of money to operate and maintain aging reactors, and some, like Crystal River, San Onofre, Trojan, Maine Yankee and more, have elected to close permanently rather than continue to pour money into them.

The other approach some utilities take to closing uneconomic and unsafe aging reactors is to try to ignore the problems and not make the necessary repairs and modifications.

That second approach–denial–is perhaps best exemplified by the Entergy Corp.’s Palisades reactor in Michigan. Decades ago–really–Palisades was identified by the NRC as being the reactor in the U.S. most vulnerable to Pressurized Thermal Shock (PTS). This nightmare scenario occurs when the reactor pressure vessel has become embrittled by exposure to heat and radiation over many years. When, for whatever reason–a pipe break for example–the reactor loses coolant, it begins to heat up quickly. Left unchecked, it will melt down. But emergency core cooling systems are designed to rush large amounts of cold water into the core and cool it down that way. The problem is that a reactor vessel susceptible to PTS could crack, and all that cooling water would simply drain out and the reactor would melt down. It’s like putting cold water in a hot wine glass.

Our friends at Beyond Nuclear, Don’t Waste Michigan, and other groups have been challenging the license renewal of the Palisades reactor for years, based primarily on that NRC finding of its pressure vessel embrittlement. For its part, Entergy says the pressure vessel is just fine. Entergy’s statement is based not on direct observation of Palisdades’ vessel, however, but on a paper analysis of apparently generic pressure vessels. This ignores that how the pressure vessel was constructed and what materials were used in that construction, both of which vary from reactor to reactor, can greatly affect the rate of embrittlement. But in November, the NRC Commissioners overruled the Atomic Safety and Licensing Board established to hear the license renewal challenge and denied the groups a hearing on the issue.

Now, however, as explained in this quite good report from SNL, Beyond Nuclear says it has unearthed new information showing that Palisades’ prior owner, Consumers Energy, understood that its vessel was a problem and had decided to anneal the vessel to strengthen it and reduce the risk. However, annealing a pressure vessel from an operating reactor would not only be extremely expensive, it has never been done. So Consumers Energy never actually undertook the task and was relieved (probably thankfully) from doing so when it sold the reactor to Entergy, which has focused only on paper fixes to the problem. Beyond Nuclear says this information shows that both a hearing should be held and that the reactor is dangerously embrittled.

Actually, I can confirm that Consumers Energy did indeed understand the problems with its vessel, and that it was planning to try to anneal the vessel.

A couple of decades ago, I testified at a hearing before a House Energy Subcommittee. I don’t remember what the hearing was about, or exactly when it was held. It was long enough ago that I don’t have that information on computer–it’s in files somewhere in my office but I haven’t actually been to my office in a while; for health reasons, I’ve been forced to work from home. But I do remember this very well: testifying with me (or, more precisely, against me) was the CEO of Consumers Power. And during a break in the hearing, we began chatting and I asked him about Palisades and the shape of its pressure vessel. He admitted it was severely embrittled but said it was no problem, the utility was planning to anneal it. I suggested that annealing was not exactly a common practice and asked him about its cost and effectiveness. He wouldn’t give me a cost estimate, but said it was manageable and sloughed off any concern that the process wouldn’t work.

I doubt this recollection would hold up in court, especially in an NRC proceeding, which is normally stacked against challengers like Beyond Nuclear. But there is no doubt whatsoever in my mind that it corresponds exactly with the “new” information the group uncovered: Consumers Energy recognized the problem and had plans to address it. I don’t know why the utility didn’t proceed with the process–probably it would have been far more expensive than its CEO admitted to me. And that’s probably why Entergy has preferred to try to paper over the problem rather than address it substantively.

Indeed, if Entergy were forced to actually fix Palisades’ embrittled vessel, it would probably also be forced to close the reactor instead. The economics wouldn’t make sense.

Paper fixes to serious nuclear safety deficiencies may satisfy the NRC, but they shouldn’t satisfy the people of Michigan who will have to live with the consequences if that PTS scenario ever does occur. Because, as Consumers Power recognized a couple of decades ago, the risks are far too real.

Michael Mariotte

January 11, 2016

Permalink: https://www.nirs.org/pts-at-palisades-yes-they-knew/

Your contributions make publication of GreenWorld possible. If you value GreenWorld, please make a tax-deductible donation here and ensure our continued publication. We gratefully appreciate every donation of any size.

Comments are welcome on all GreenWorld posts! Say your piece. Start a discussion. Don’t be shy; this blog is for you.

If you’d like to receive GreenWorld via e-mail, send your name and e-mail address to nirs@nirs.org and we’ll send you an invitation. Note that the invitation will come from a GreenWorld@wordpress.com address and not a nirs.org address, so watch for it. Or just put your e-mail address into the box in the right-hand column.

If you like GreenWorld, help us reach more people. Just use the icons below to “like” our posts and to share them on the various social networking sites you use. And if you don’t like GreenWorld, please let us know that too. Send an e-mail with your comments/complaints/compliments to nirs@nirs.org. Thank you!

GreenWorld is crossposted on tumblr at https://www.tumblr.com/blog/nirsnet

Metallurgy is a topic I have an understanding of. Because metal fabrication has been my lifetime

occupation, I have learned a lot about metals along the way. Annealing the pressure vessel means to soften the grains of the material in the vessel. With the vessel’s grains closer together now (brittle), caused from the heat and radiation inside the vessel, softening 6″ of such a structure would be a challenge for sure.

Would the vessel be heated on one side with something like an electric blanket? Or this heating could take place during a fuel outage? If so, with the reactor “empty” the “electric” blanket(s) could be on both sides, top & bottom. Then the metal would need to be heated way up ( approx. 1,400-1,650 deg. F). This would permit the grains in the metal to “relax” or go back to their original grain structure. Once heated, the vessel would need to stay at the appointed temp. for a specific amount of time. The vessel temp. would need to be brought down slowly (post heat) for a specific amount of time. Finally, allow the vessel to come to “room” temp. Then check it out.

The lines that are connected to the reactor are probably affected by the heated water & radiation that runs thru them. They too, would all be subject to radiation “decay” and some embrittling. Better check them out as well.

In the investigation we need to know: did the seller inform the buyer of the vessel’s status?

Did the buyer not check on the condition of the reactor vessel before buying? Are there records of this?

Great article Mr. Mariotte, like always.

Great article, Palisades is in my home turf now, so I am interested in killing this one.

Legal technical point, which could be very important. If you can find notes or a writeup from your testimony and you can consider these to be “business records” then they are immediately evidence and not just hear-say